When it comes to keeping your pipes clean and your drains unclogged, there are several options to choose from. The two main options that plumbers prefer are the use of plumbing snakes (or plumbing augers) and hydro jetting.

The use of plumbing snakes is rather classic. That’s why many plumbers today use hydro jetting which is a more innovative solution for more blockages. However, each type of clog require a unique technique and it’s upon the plumber to decide which technique works best.

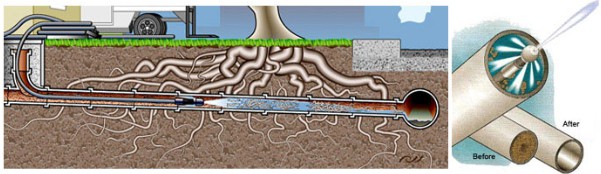

In hydro jetting, water at very high pressure is used to scour the inside surfaces of pipes. This water helps in removing grease, scale, and any other debris that might have built up on the walls of the pipe over time. When properly done, hydro jetting can achieve a thorough cleaning of the pipes.

How Does Hydro Jetting Work?

Hydro jetting is a method used by experienced plumbing contractors to clean slow or clogged sewage lines. Hydro jetting systems normally use water at a pressure of about 3,500 pounds per square inch or more, which works very effectively.

The plumber will first carry out a video inspection to determine the cause of the problem and its location. After inspection, a self-propelled nozzle is fed into the pipe or drain and it will blast water into the pipe or drain at a high pressure to remove the build-up and blockages.

Video inspection is also necessary to reduce the possibility of backflushing of sewage into other areas.

If the roots of a tree cause the blockage, a snake may first be used to tear them up, especially if they are heavy roots that water cannot tear through.

Hydro jetting doesn’t solve problems caused by broken pipes and, because of the high pressure, it could cause the weakened areas of the pipe to break. That’s why only an experienced plumber can carry out the process to deliver the right water pressure for the blocked pipes and for the problem at hand.

In their normal working conditions, a sewer or plumbing system uses gravity to remove the build-up and blockage. But a hydro jetting tool works from bottom up.

The nozzle is inserted into the downstream part of the system and the pressured water has to move upward as it scours the pipes and dislodges the debris in the pipes which then move down by gravity.